|

|

CATRIDGE HEATERS : CATRIDGE HEATERS :

|

|

Cartridge Heaters manufactured by H.K.TEMPSENSORS(INDIA) are suitable for many diverse applications. High-Density Cartridge Heaters(even heat profile and max. temp of 750 deg C with various watt density options available) are designed and manufactured out of experience of many years, thus the performance and life expectancy superseeds other cartridge heaters. Low Watt Density Cartridge Heaters(for temperatures exceeding 300 deg C with max wattage densities of 30 to 45 watts per square inch) are an economical alternative that can be used in applications requiring lower operating temperatures and watt densities.

Both high density catridge heaters and low density catridge heaters are available with in-built thermocouples for providing accurate control. |

| |

Applications : |

| |

| Hot Runner Bushings. |

|

Marking And Sealing Machinery. |

| |

|

|

| Packaging Machinery. |

|

Shoe Making Industry. |

| |

|

|

| Die And Platents. |

|

Hot Stamping. |

| |

|

|

| Plastic Injection. |

|

Glue Guns And Wax Pots. |

| |

|

|

| Medical And Laboratory Equipments. |

|

Heat Sealing. |

| |

|

|

| |

|

|

|

| |

|

|

|

|

|

MICA HEATERS MICA HEATERS

|

|

Mica Band Heaters consist of resistance ribbon/round wires wound over mica.Variety of different sheath material like brass,MS and chrome nickel steel.Special high grade mica insulation for superior thermal conductivity.Expandable to fit around the BarralO.D. easy installation &removal.They are available in various lead terminations &clampings,robust terminal junction with specially designed chrome nickel steel protection cap.HKT’s mica heaters are Engineered with superior quality nichrome wire for uniform temperature and amperage carrying capacity designed for temperatures upto 400 deg C. |

|

| |

| APPLICATION : |

| |

• widely used in injection moulding.

• blowmoulding.

• film extruders.

• all plastic & rubber processing machinery.

• laboratory equipment. |

| |

|

| |

|

|

|

CERAMIC BAND HEATERS CERAMIC BAND HEATERS

|

|

Ceramic Band is manufactured by placing spirally wound Nichrome 80/20 resistance wire coil in ceramic insulators and covered by outer chrome nickel steel sheath with power saving options. HKT’s Ceramic band heaters use special high grade steatite insulators for superiorthermal conductivity. These heaters have efficient heat transfer even on irregular surfaces in comparison to mica band heaters.HKT’ s ceramic band heaters conserves energy giving power saving of 30 % with improved heating efficiency upto 55 watts per square inch.Expandable to fit around the BarralO.D. easy installation &removal. They are available in various lead terminations &clampings,robust terminal junction with specially designed chrome nickel steel protection cap.HKT’s ceramic band heaters are Engineered with superior quality nichrome wire for uniform temperature and amperage carrying capacity designed for temperatures upto 600deg C. |

| |

| |

APPLICATIONS : |

| |

| |

• widely used in injection moulding.

• blowmoulding.

• film extruders.

• all plastic & rubber processing machinery. |

| |

| |

|

| |

|

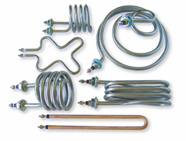

TUBULAR HEATERS TUBULAR HEATERS

|

|

Formed Tubular Heaters is supplied in Chrome Nickel Steel with nominal sheath diameter of 6.80mm, 8.00mm and 10.70mm. Standard elements have a threaded terminal post which gives a cold section of approx 40mm minimum. |

The helical wound heating wire is made of a high temperature resistant NiCr alloy. And the insulation consists of superior grade of magnesium oxide (MgO). As the heaters are swadged, even at high sheath temperature they have excellent electrical insulation and a high heat transfer. To prevent the heater from moisture the connection ends are sealed with sealing components.

For manufacturing formed elements it is necessary to have a accurate dimensional sketch showing all the centre distances, radius and degrees, thus they need to be provided while placing the order. |

| |

| APPLICATION : |

| |

| • Hot runner manifolds. |

| |

| |

|

| |

MICRO TUBULAR COIL HEATERS MICRO TUBULAR COIL HEATERS |

|

Micro Tubular Coil Heaters are manufactured in two standard diameters, 1.5 mm and1.8mm (0.059” & 0.07”). These heaters are swaged and compacted to these diameters and fitted into special clamps to tighten over circular parts for heating purpose. |

The 1.8mm diameter Micro Tubular Heater is formed into a coil of predefined dimension and equipped with a special cover for easy fittment. This special cover called Axial clamp allows front end loading and adjustability. Such easy handling saves hours of downtime in case of heater failure in a Multi - Cavity mold. These heaters are offered with staggered. |

| |

| |

AXIAL CLAMP |

| |

| |

The 1.8 mm diameter Micro Tubular Heater is formed into a coil of predefined dimension and equipped with a special cover for easy fittment. This special cover called Axial Clamp allows front end loading and adjustability. Such easy handlling saves hours of downtime in case of heater failure in a Multi - Cavity mold. These heaters are offered with stagered cold leads of 5" & 7". |

| |

| |

APPLICATION : |

| |

| |

|

| |

|

|

|

|

|

|

|