|

|

STRAIGHT THERMOCOUPLE ELEMENTS STRAIGHT THERMOCOUPLE ELEMENTS

|

|

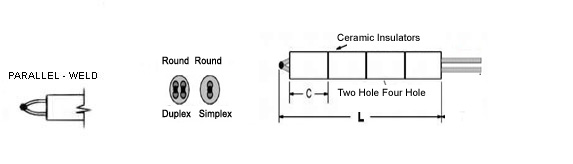

The Straight Thermocouple Elements illustrated below are replacement elements for the use in HKT'S complete Industrial Thermocouple. These replacement elements are also compatible for use in other manufacturer's thermocouple assemblies. These thermocouples are available as bare wire or ceramic insulated elements and also with special constructions dessigns as per customer requirements. |

|

|

|

90 DEGREE BENT THERMOCOUPLE ELEMENTS 90 DEGREE BENT THERMOCOUPLE ELEMENTS

|

|

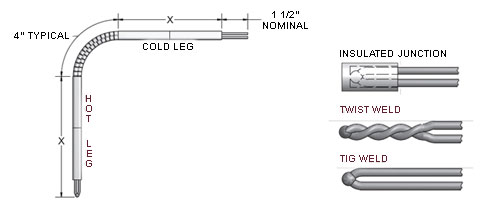

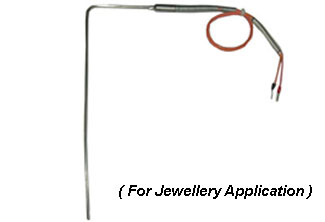

HKT'S 90 deg. bent Thermocouple Elements offer advantages as they do not require removal of the enclosures or assembly components. These elements are simple, inexpensive and can be used for wide temperature ranges. Our range of thermocouple elements are stable and sensitive and find application in varied industries. Manufactured as per client's requirement, we offer these elements at market leading prices. |

| |

|

| |

|

|

STRAIGHT THERMOCOUPLE ASSEMBLIES WITH CERAMIC PROTECTION TUBE STRAIGHT THERMOCOUPLE ASSEMBLIES WITH CERAMIC PROTECTION TUBE

|

|

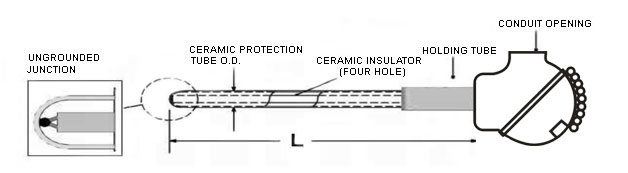

The straight noble and base metal thermocouple assemblies, with MULLITE (Melting point 1840 deg c) and alumina protection tubes,are those most commonly used in high temperature process heating application. These assemblies are available with a variety of process mounting assembly options are available as shown below. Special construction designs are also available as per customer requirements. |

| |

|

|

|

HIGH TEMPERATURE THERMOCOUPLES WITH SINGLE/DOUBLE PROTECTION TUBE HIGH TEMPERATURE THERMOCOUPLES WITH SINGLE/DOUBLE PROTECTION TUBE

|

|

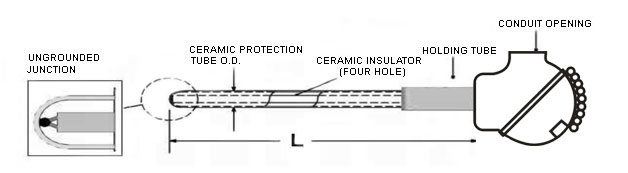

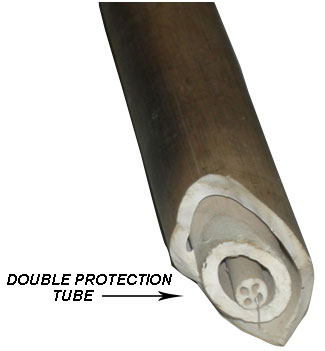

Exotic thermocouples probes are designed for use in extreme temperatures,up to 2315 DEG C (4000 DEG F). These probes utilizes either platinium/rhodium (TYPE R, TYPE S OR TYPE B) or platinium/rhenium (TYPE G, TYPE C OR TYPE D) elements,with a variety of insulations and sheath materials. Depending upon the sheath material selected,these probes may be used in inert, oxidising, reducing or vaccum conditions. The maximum temperature is based on the lowest max. Temperature of the element,insulation or sheath material. Five cold end probe terminations are available:Replacement probe,subminiature or standard size ceramic connector,heavy duty standard size,molybdenum sheathed nylon connector or transition joint. High Temperature Thermocouples are specifically designed for durtbility and reliability in high temperature applications to 4200° F (2315° C). Such applications generally involve oxidizing, reducing, inert gas or contamination atmospheres that challenge the life of the thermocouple. Special construction designs are also available as per customer requirements. |

| |

|

|

| |

| |

|

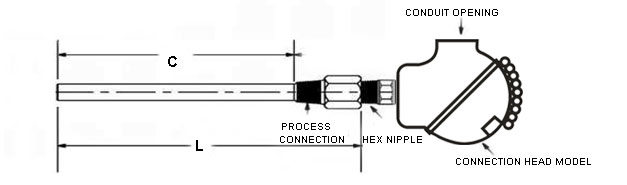

STANDARD THERMOCOUPLES WITH PRESSURE TIGHT THERMOWELLS STANDARD THERMOCOUPLES WITH PRESSURE TIGHT THERMOWELLS |

|

Thermowells are pressure tight receptacles that extends the life of a temperature sensor in environments where the sensor is not chemically compatible with process media or the sensors does not have the mechanical strength to withstand the process flow or pressure. Thermowell is also facilitate in removing, changing, checking or replacing sensors without draining the process system. The use of standardized thermowells throughout the plant permits easy relocation of sensors. Specially deigned thermowells along with thermocople sensors are available as per customer specifications. |

| |

|

|

| |

|

|

MINERAL INSULATED THERMOCOUPLES MINERAL INSULATED THERMOCOUPLES

|

Mineral insulated (M.I.) thermocouples are fast-responding, durable and capable of handling higher temperatures. Mineral Insulated (M.I.) thermocouples responds fast because the protective outer sheath allows the use of smaller diameter thermocouple conductors.The rock hard compacted MgO further enhances the sensor's ability to read temperature by transfering heat quickly to the measuring junction. Mineral insulation protects the thermocouple from moisture and thermal shock and permits operating in high temperature, high temperature enviroments.Mineral insulation allows forming and bending of the thermocouple, without the risk of cracking, to meet the design requirements. Outer sheath used protects the thermcouple from oxidation and hostile environments.We also make custom mineral insulated thermcouple which include options such as lead lenghts,lead wires and terminators.

|

| |

|

|

EXPLOSION PROOF THERMOCOUPLES EXPLOSION PROOF THERMOCOUPLES

|

|

Explosoin proof thermocouple assmblies with thermowells are made FOs use in hazarodus areas. They are designed to extinguish flames inside the device,eliinating the potential for ignition of flammable mixtures in surrounding atmosphere. The required thermowels is available in standard,heavy duty and flanged constructions. The Assemblies feature Stainless Steel (SS) 316 sheaths and ungrounded (ISOLATED) junctions. They are available with stainless steel or aluminium explosion proof connection heads. |

| |

| |

|

|

|

|

|

|